Edition: Mon, 25.01.2021

On the road this week for our house magazine: Daniel Honegger

Do you have suggestions or ideas for a contribution? Send us your suggestions here:

Photo of the week: Too long for the photo studio

The semi-truck is too long for our photo studio. The all-around white background is not possible. The rest will have to be fixed by our marketing team with Photoshop.

21.01.2021, DH

Partner Refresh - online for the first time

This year, the Partner Refresher will be held via live video broadcast for the first time,

Tuesday, Jan. 26, 2021, will be the third practice session. All employees are invited to participate in this practice session.

The training session will start at 8:30 a.m. and end at 4:00 p.m.

And you can log in here:

22.01.2021, FV

Good to know:

The first test run already took place on Friday, Jan. 22, 2021. Bruno Streich and his team were on-site and transformed the workshop into a film studio just like that!

Sports scientist

The eRod serves as a demonstrator of cutting-edge technology for the Siemens Group.

When it comes to maximum driving pleasure without emissions, the KYBURZ eRod is at the forefront. At the Siemens technology group, the sports car with its powerful electric drive, equipped with high-tech sensors, is at the forefront of new technologies.

Want to learn more? Click here for the full article:

22.01.2021, FAS

Good to know:

Did you know that the most expensive eRod ever built costs over 1 million? You can see it in this picture: The 4 measuring units on the wheels are from the Kisteler company and cost CHF 250,000 per wheel.

Do you have questions about the project? Fabien Caroselli will be happy to answer them.

Solar system and battery storage

Interview with Turi.

Luca: We have two solar plants, and besides, you have built two battery storages. What is the difference?

Turi: Basically, the power of the solar panels. On the small system, we have 3kW, and on the big system, 17 kW. The second difference is that the small one has an inverter that brings 230V and the big one has a three-phase 400V. With the small system, we run the 2ndLife office, and with the big one, we feed the charging pump on the outside parking lot. The large battery storage system will also feed the battery recycling system.

Luca: What motivated you to develop this plant as a product of KYBURZ?

Turi: Yes, electricity was and is my profession. So about three years ago, we planned the small solar plant. We bought the solar panels and assembled the complete system with battery storage by ourselves. About 2 years ago we bought the bigger inverter. At that time, the landlord was renovating the roof, and at the same time, he installed the solar panels for us. We connected the inverter and fed the solar panel's power into the grid for about 1 year. Somehow it didn't give me any peace of mind, and so the second battery storage system was created, which for safety reasons was set up with the block system in three boxes of 16 cells each.

Luca: What were the biggest challenges in setting up the system?

Turi: The first hurdle was that the solar panels and the inverter were subjected to an acceptance test by the Certum company, and they checked everything down to the last detail, from the feed-in with the panels to the lightning protection and the fuses to the labeling of the boxes. The second thing is happening in the current phase, where I am monitoring the batteries with Fleet and eliminating any possible faults.

Luca: How much is still missing until a flawless product?

Turi: The failures only happen when a cell is too low, and our BMS does not manage to rebalance the cells at the moment. Otherwise, the system works perfectly.

Luca: Who do you think will set up such a system at their home?

Turi: A single-family homeowner who anticipates that electricity will be a little scarcer will set up such a system to be autonomous. As more and more electricity is consumed, our existing grid could also become too weak, so we will have to rely on decentralized electricity storage. It may well be that someone with a larger system could support his neighboring houses in such a case.

Luca: If you listen to your developer's heart, what is the next project you want to tackle?

Turi: "Laughs." At the moment, I have enough projects to get to the finish line. Who knows what else is coming up.

Luca: We at 2ndLife appreciate your work very much, on the one hand, the energy you put into the battery storage, but on the other hand also for the many small and big details you do for us. Thank you.

22.01.2020, LUB

| A solar system with battery storage | Small | Large | ||

| kW Power inverter: | 3 kW | 10 kW | ||

| kW Solar panel power: | 3 kW | 17 kW | ||

|

Battery storage capacity |

12 kWh | 12 kWh | ||

| Output voltage: | 1Phasig 230V | 3Phasig 400V | ||

| Fleetmonitored: | yes | yes |

Do you have questions about this project? Then contact Turi directly.

Object of the week: Cabriobox

The requirements set for the development of the convertible box were high: weather protection, simple, two-sided operability, safety in the event of collisions, and others.

After initial, unsatisfactory metal constructions, the current plastic Cabriobox was developed in cooperation with an external design office and won 2nd prize in a design competition for packaging.

The double-walled walls and the bottom of the box are produced in France. A tube made of polypropylene is inflated in a mold until it has the desired shape. The textile cover brackets, which can be locked in various positions, are produced in Switzerland using injection molding technology.

Avantex from Trimbach supplies the canopy. Swiss military backpacks are made of the same durable material. In an endurance test at KYBURZ, the canopy survived 300,000 open-close cycles.

Good to know:

We have a patent and design on the convertible box. Therefore, it may be manufactured and sold exclusively only by KYBURZ - both in Switzerland and in the EU.

22.01.2021, DH

| Dimension: (LxWxH) | 555 x 667 x 393 mm | |

| Weight: | 9.4 kg | |

| Material: | Polypropylene PP (walls), Polycarbonate Polybutylene Terephthalate PC/PBT (poles), Textile | |

| Sales price: | CHF 484.65 incl. VAT | |

| Internal volume: | 104.8 l | |

| Cycle stability: | >300'000 cycles (Soft top) |

The latest TECH TALK from and with Martin

Every week an episode from my new video diary TECH TALK will be published. It will be published on our homepage and on YouTube. Become an insider and follow my YouTube channel. You will get interesting insights into the world of KYBURZ.

The MaXX2 is available in two widths

The first MaXX2 was delivered just under a year ago. In contrast to the original MaXX, the new model was wider at the rear and thus safer. Our Dutch reseller HUKA BV now reported that this greater width is a problem in certain cases.

This is not a problem for KYBURZ: we developed a second version with a narrower chassis. The first narrow MaXX2 was delivered to Holland last week.

Good to know:

All KYBURZ vehicles are built tough. However, the MaXX2 is the front runner in terms of load capacity. It is designed for people weighing up to 300 kg (235 kg for the narrower chassis).

A handful of MaXXs is in use in Switzerland and Germany. More than 200 MaXX and MaXX2 are operating in Holland.

21.1.2021, DH

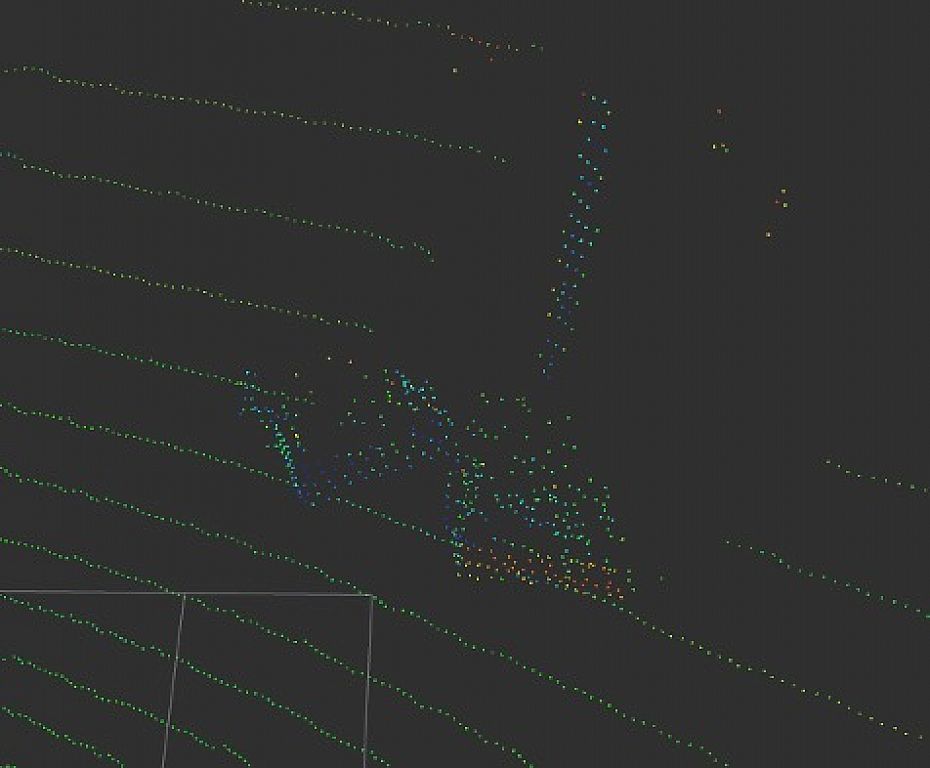

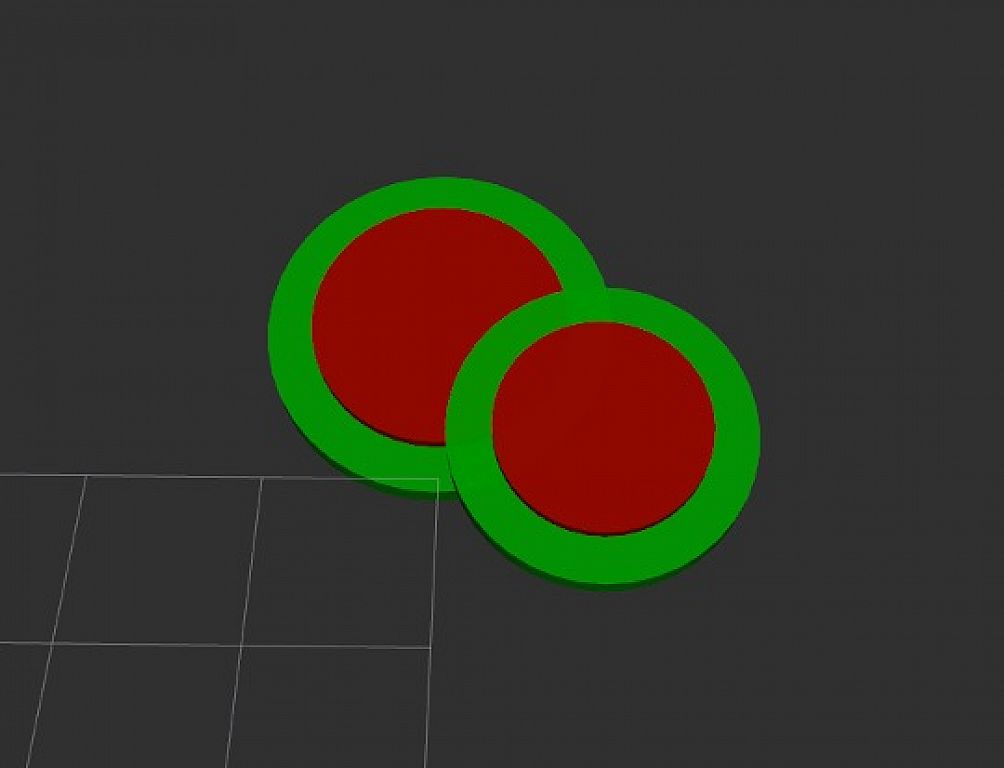

What special sensors our Autonomous Plus 2 carries

For an autonomous vehicle like "Nina," it is of utmost importance to detect insurmountable obstacles in time and reliably. First and foremost, collisions with other vehicles and other objects can be avoided. In a further step, such obstacles can also be actively avoided. What seems self-evident and, in most cases, simple for a human driver poses a great challenge for a robot. Therefore, for reliable detection of the environment, usually different sensor technologies and dozens of sensors are placed around an autonomous vehicle. This article will take a closer look at obstacle detection using a LIDAR sensor.

LIDAR stands for "LIght Detection And Ranging" and uses a laser beam to measure the distance to objects in the environment (see Figure 1), tens of thousands of times per second. The information that the sensor collects in this way is summarized as a cloud of points (see Fig. 2) and forwarded 10 times per second to the computer responsible for perception and trajectory planning for further processing. The computer processes the received data according to the following procedure:

| 1. | Ground removal: | Removing the points that hit the ground | ||

| 2. | Downsampling: | Simplification of the data points | ||

| 3. | Clustering: | Combining the points into groups | ||

| 4. | Tracking: | Were the groups already in the last scan? Have they moved? |

The groups that were detected with a high degree of certainty, i.e., several times in succession, are combined in a final step to form an obstacle. The obstacle is composed of simple shapes that reproduce the obstacle's contour (see circular shapes in Figure 3). The obstacles are then further used for the course planning in this form.

If you want to learn more about this topic, I recommend you to have a look at this thesis of two BFH students, which provides a good overview of the topic:

The website is in German.

21.01.2021, MVB

Fleet-Box OCV – the youngest member of the KYBURZ Fleet family

To better meet the needs of simple data collection tasks in harsh environments, a simple, waterproof, and robust fleet box was evaluated. Slightly larger than a matchbox, it can be installed in almost any location, in-vehicle interiors, and outdoors exposed to wind and weather. Thus, the box is suitable for applications on two-wheelers, boats, or construction machinery.

"We have good, but still little experience with the box so far," says Mario Fischer, responsible for vehicle engineering at Fleet, "300 units have already been ordered. That's why we've been running intensive test series for 2 months to be able to operate the box as optimally as possible." In this case, that means capturing as much useful information as possible while keeping SIM costs and power consumption as low as possible.

The first major order is to determine the operating times of construction machines. This only makes sense for a construction company if the large excavators and all the small machines supply data. That's why installation must be simple and operation cost-effective. This is exactly what we achieve with the OCV Box.

Later, batches are fully configured and delivered with KYBURZ glue from the manufacturer. For the first 300 devices, we still do the configuration, SIM insertion, and label application ourselves. The KYBURZ Fleet-Box OCV will soon be seen in production at Tannenstrasse.

21.01.2021, HP

New business area: Sustainability

KYBURZ Switzerland is strongly committed to sustainability. These activities are now combined in one business unit under Luca Botta's management.

The reconditioning of the 2ndLife vehicles, the work around the battery storage, and battery recycling are part of this new unit.

The reconditioned vehicles will continue to be offered under the 2ndLife name.

JAN. 21, 2021, DH

Want to learn more about sustainability? Luca Botta will be happy to provide you with information.

Staying fit is the order of the day

According to the BAG, no more fitness classes may occur until the end of February. This also affects our Thursday morning lessons at Move & Dance!

To keep you fit anyway, here are a few ideas:

- Brisk walk 10'000 steps per day

- Jogging on Tuesday at noon

- On Youtube, you can find many different free lessons (Pilates/Yoga/Stretching....). All you need is a mat and motivation! Try it out.

We hope to start again in March.

Until then, sporty greetings

11.01.2021, SL

The history of the eTrolley 7+1

We all know the eTrolley 7+1, but do you know how the vehicle came into being? We have created a chronological series of pictures for you. Hard to imagine how the first eTrolley7+1 looked like if you know today's model :)

Have fun watching it.

21.01.2021, FAS

The document is in German.

Would you like to learn more about the eTrolley 7+1? Rolf Menzi will be happy to provide you with information.

Good to know:

The development of the eTrolley started around 2010/2011 for a project with the Luxembourg Post. The design was done together with Mark Wyss. In 2012 the first eTrolley V1 was delivered. Already in 2013, the eTrolley delivery to the Austrian Post followed.

From 2014 the eTrolley7+1 with lithium battery was developed for Deutsche Post. In the project team were Rolf Menzi, Mark Wyss, and Wilfried Hahn, of course, with support from the other departments and design by Christian Benz. Currently, Rolf Menzi is responsible for the eTrolley.

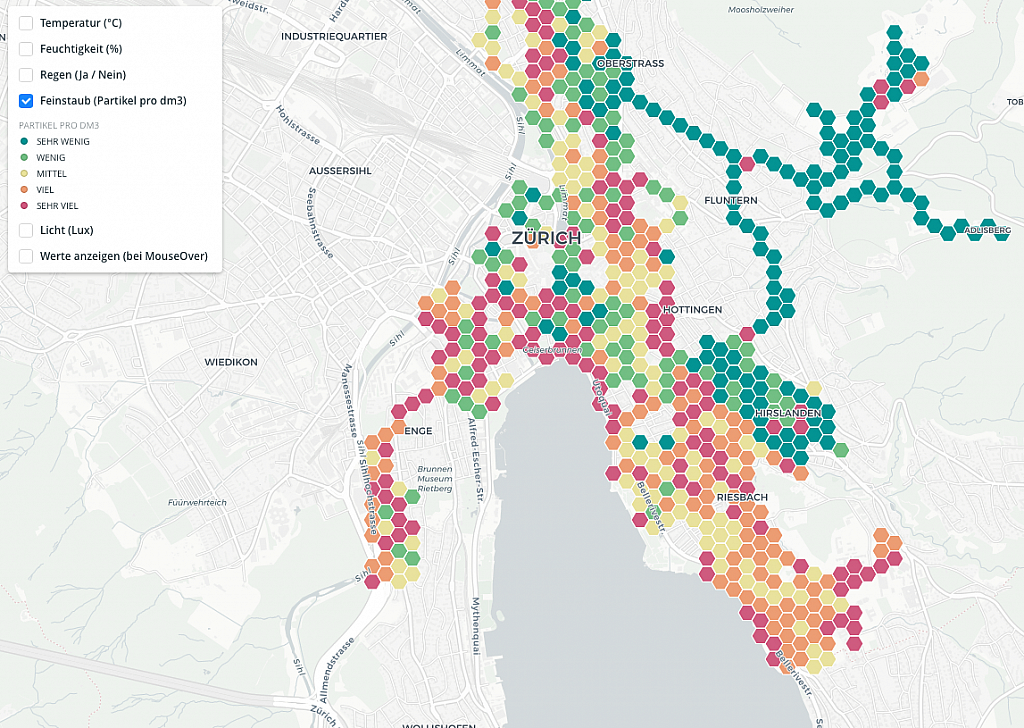

KYBURZ DXP Weather Station

With the KYBURZ DXP Weather Station, it is possible to collect weather data over longer periods of time. It measures temperature, precipitation, humidity, light, and air quality.

The Weather Station results from a collaborative project: the two departments Research and Fleet Management worked closely together.

The live measurement data can be accessed via KYBURZ Fleet Management. More information about the Weather Station can be found here:

Do you have any questions about Weather Station? Erik Wilhelm will be happy to answer them:

22.01.2021, JAG

Good to know:

The KYBURZ Weather Station has already been on the road since 2019. Started in Oerlikon, it is currently on the road at the Gold Coast in Zurich. Here you can follow the Weather Station:

The City of Lucerne drives DXS

2 years ago, the first test drives with the KYBURZ DXS took place in Lucerne. Now several KYBURZ DXS with trailers is already in use. The vehicles are used in the civil engineering office. For the pedestrian zone and narrow paths, the KYBURZ DXS is perfect for them. "We especially appreciate the high flexibility and that you don't need a driver's license cat. B is required," says Heinz Zurkirchen from the service of the works. In the next step, the DXS will also be used in the Lucerne municipal gardening department.

21.01.2021, JAG

Good to know:

Employees from the Werkdienst of Lucerne's city maintain and repair the vehicles themselves. They have attended KYBURZ's service level B training.

Are you interested in the KYBURZ DXS? Jürg Geiser will be happy to provide you with information.

Jürg Geiser delivered another KYBURZ DXS with a trailer in December.

Proud ePedelec tester at Deutsche Post

Serkan Celik is a delivery man at Deutsche Post. On his almost 18 km tour, he delivers mail to over 100 recipients for around 4½ hours with KYBURZ support. Since November 18, he has been a selected tester in Starnberg, a small excursion and recreation town 25 km southwest of Munich at the northern end of the lake of the same name. The large-scale ePedelec field test will last until the end of March 2021. By that time, as a representative of his branch, Celik is required to make known his assessment of the practical suitability and potential improvements of his new vehicle. He and 10 other product testers have every right to be proud of this activity.

19.01.2021, HPE

The report is in German.

For detailed information, please contact Hans-Peter Erni.

Reconstruction kitchen in service

The Electronics Competence Center's creation and the move to Industriestrasse freed up the Service Electronics room. To make the best use of the newly gained space, it was decided to relocate the break room.

Since about 10 people share the lunch table every day, it was getting a bit cramped in the gallery workshop anyway. Without further ado, the kitchen was moved to the new location, which is now separate from the workshop.

The conversion took 2 days and was realized by the KYBURZ team. Arthur Bäuerle took care of the cables, while Michele Grosso did the sanitary installation. Altin Gashi actively supported the conversion. At the same time, 2 workstations for office work were set up in the gallery workshop, as well as the electronics station.

As soon as the Corona fiasco is over, a sofa corner for quiet minutes and the Töggeli box for the sporty part will be installed in the break room. Until then, fixed benches will be distributed around the room to follow all the rules, yet eating together is possible.

22.01.2021, AZ

A day in the life of Filloreta Gecaj

Erza Mehmeti: How long have you been with KYBURZ?

Filloreta Gecaj: I have been with KYBURZ since April 2019.

Erza: What are your activities?

Filo: On the one hand, I am responsible for arranging appointments for Martin Kyburz, and on the other hand, I also prepare meetings, including presentations and writing minutes. I am also responsible for the audits: internal, ISO 9001 (quality audit), and ISO 14001 (environmental audit), including coordination, implementation, and follow-up. This means that I arrange all the appointments, write the minutes during the audit and then create a final report. Afterward, I distribute the tasks to the responsible employees. I am also responsible for external training/workshops and filing the training documents. I am also the contact person for the cleaning staff in Freienstein. This includes creating cleaning schedules, organizing substitutes, and material management. Besides, I have been helping out in the Fleet one day a week since around April 2020.

Erza: What is your typical daily routine?

Filo: I arrive every morning around 08:30 and check my emails first. Most of the time, I know what needs to be done that day, and otherwise, I prioritize my tasks using Microsoft To-Do. Even though it sounds like every day is the same, it's not. I don't have the typical recurring activities, such as processing mail. Every task is different, and that makes my workday exciting.

Erza: What do you like? What not so much?

Filo: I like the company culture and the people in the company. Through my activities, I have the unique opportunity to get an insight into all areas of the company. This makes my work very complex and varied. What I like less is that the company is spread over three locations. This makes communication between the departments more difficult.

Erza: What do you like to do in your free time?

Filo: In my free time, I like to meet my friends, go to the movies or out to dinner. Traveling is also one of my passions. However, the Corona situation is limiting many of my free time activities.

22.01.2021, ERM

Webshop: Article of the week

Handlebar heating

Do you get chilly, and the handlebar gloves are good, but not enough? Then we have the right thing for the cold winter days. Equip your vehicle with our grip heater, and cold hands are a thing of the past. The grip heater can be retrofitted to the DXP & DXS from version 4.0.

You can easily purchase the grip heater from our webshop—the price incl. The retrofit is CHF 365.- incl. VAT.

You can purchase the set in the webshop to install it yourself or make an appointment for the installation. If you have any questions, please contact Matthias Röthlin directly.

09.12.2020, MAR

Arrange your appointment for the assembly

Change of the cleaner in Freienstein

In Freienstein, Ms. Bekteshi and Ms. Hoxha have been cleaning our offices and workshops from January 1, 2021, until approximately the end of June 2021. As you can see from the cleaning schedules, Ms. Hoxha cleans the service, research, and offices of the ePedelec team. Ms. Bekteshi will take care of the rest.

Documents are in German.

We ask you to clear your work areas in the evening so that our ladies can clean them better.

Feedback and input can be forwarded to Fillo.

17.01.2021, FIG